Hydraulic cylinders are hydraulic circuit elements that convert hydraulic energy into mechanical energy and obtain linear motion and force.

Many different classes and types of hydraulic cylinders can be produced according to the intended purpose. As Hidrolift, we produce four types of hydraulic cylinders. You can access these cylinders and their connection types via the links below.

Please contact us for any custom or standard production of cylinders.

-

Single-Acting Hydraulic Cylinders

These are cylinders in which cylinder movement in one direction is provided by hydraulic oil pressure, while cylinder movement in the other direction is provided by another external factor (the weight of the lifted load, spring force, etc.).

Spring-Return Hydraulic Cylinders

-

Spring-Return Hydraulic Cylinders

These are cylinders in which cylinder movement in one direction is provided by hydraulic pressure, while cylinder movement in the other direction is provided by the spring effect. The cylinder works in one direction, while the spring force is limited by the shape and characteristics of the spring. Spring force is usually achieved using cup springs or compression springs.

Although the springs used in these cylinders vary according to the intended purpose, spring force is generally used to restore the cylinder.

-

Plunge Type Hydraulic Cylinders

These are cylinders in which cylinder movement in one direction is provided by hydraulic pressure, while cylinder movement in the opposite direction is provided by the weight of the lifted load. The load lifted by these cylinders should be heavy enough to restore the cylinder to its previous position.

They are cost-efficient since there is no need to hone the barrel in plunge type cylinders. However, the entire bearing of the cylinder tie rod is made over the front cover and the bearing length is sometimes insufficient. In this case, the barrel is honed, a piston is added to the cylinder and the bearing length is increased.

-

Double-Acting Hydraulic Cylinders

These are hydraulic cylinders in which cylinder movement in both directions is provided by hydraulic pressure. They can be produced as single-rod and double-rod.

-

Single-Rod Hydraulic Cylinders

These are the most common hydraulic cylinders. The cylinder generates both thrust and traction forces. Since the surface areas in thrust and traction are different, the forces obtained at the same pressure are different as well.

-

Double-Rod Hydraulic Cylinders

The cylinder generates both thrust and traction forces. Since the surface areas in thrust and traction are the same, the forces obtained in thrust and traction and the operating speeds are the same as well.

-

he difference between telescopic cylinders and other cylinders is that telescopic cylinders have shorter assembly length when in closed position and have a longer stroke value than cylinders of the same size.

The number of cylinder stages varies according to the size of the assembly location. The length of a telescopic cylinder in closed position is normally half to a quarter of its open length.

Telescopic cylinders are classified as single-acting and double-acting according to their effects.

-

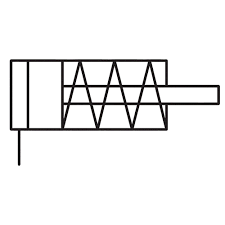

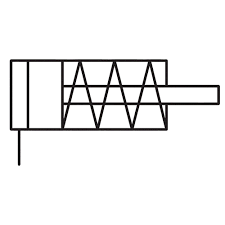

Single-Acting Telescopic Cylinders

These cylinders can lift loads as much as the force generated by the smallest stage diameter and return with the weight of the load. As the pressure and the number of stages increase, so does the outer diameter of the cylinder. These factors should be considered when choosing the assembly location.

-

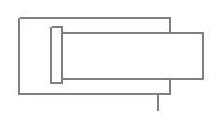

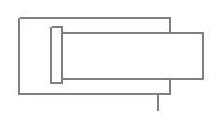

Double-Acting Telescopic Cylinders

These cylinders generate both thrust and traction forces. Two-stage telescopic cylinders are the most common. As the number of stages in double-acting cylinders increases, the design becomes more complex and the cost increases.

-

-

These cylinders are generally used in presses. They consist of two embedded cylinders at different diameters. The small-diameter stage ensures rapid progress due to the narrow cross-sectional area. Meanwhile, the large-diameter stage provides a higher amount of force compared to the small-diameter stage.

-

These cylinders allow for greater forces with the same system pressure and the same piston diameter. The piston of one of the cylinders is mounted in tandem (end-to-end) with the rod of a second piston, which provides the transfer of force. This provides more force compared to a cylinder with the same cross-sectional area and pressure.

-

A control rod is threaded on the hydraulic cylinder rod and connected to a center gear. The reciprocating motion of the cylinder allows the center gear to rotate. This way, linear motion is converted into rotary motion.

The stroke of the cylinder determines the angle of rotation of the center gear, while the force generated by the cylinder and the distance between the gears determines the generated torque.

-

Cylinder Connection Types

Cylinders are generally designed to transmit linear loads. The geometrical linearity of the assembly location directly affects the life of the cylinder. There should be no stiffness between the connection points and they should not be subjected to radial load, if possible. Spherical bearing connections are especially helpful in balancing potential angular loads.

Cylinders can be connected to the assembly location in various ways. The most common connection types according to ISO 6099 are as follows.

-

MB- Body Assembly

ME- Front or Rear Cover Assembly

MF- Flange Connection

MP- Lug Connection

MR- Screw Connection

MS- Foot Connection

MT- Trunnion Connection

MX- Stud Connection

-

RP- Flat Connection

RE- Lug Connection

RT- Screw Connection

RF- Flange Connection

RS- Sphere Connection